Working in coordination with leading implant and medical component manufacturers, Wheelabrator has designed, built and installed many customised shot peening, cleaning and polishing solutions.

Depending on the component and the treatment required, air and wet blast techniques have been developed to meet your exacting needs.

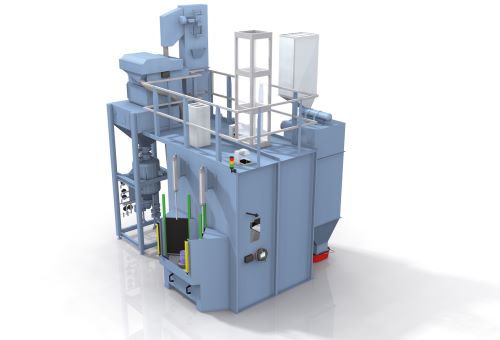

Custom-designed Airblast Equipment Solutions for Peening Implants to Increase Strength and Durability

For a precise and repeatible process, peening equipment is often automated. In addition to the actual blasting/peening or cleaning technology, Wheelabrator has developed and delivered complex materials handling processes utilising automation and the creation of component holding tools and masks.

Surgical Standard Cleaning

Wet blast technology solutions minimise dust and other contamination and so are popular in this industry sector. Machines can be manual (cabinets) or automated.

Technology:

Airblast

Application:

Cleaning

Satellite Turntable Machine ST

Highly flexible machine range, with one or two satellite tables, for light up to heavy parts.