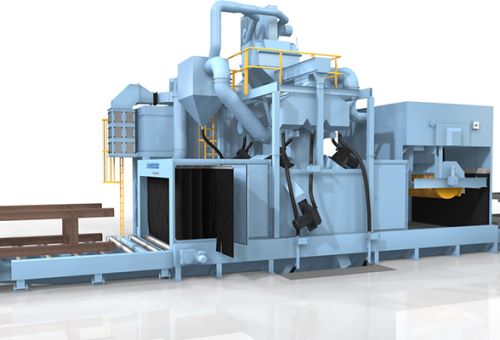

Wheelabrator specialises in custom-designed peening and surface preparation solutions to provide a solution to your challenges.

For descaling steel shapes, flats and fabrications, Wheelabrator has designed and delivered automated airblast and wheelblast solutions, including Roller Conveyor blast machines, Hanger type/Monorail blast machines, Bogie Table/Work Car blast systems, Skew Roll blast machines, plate and structural steel Preservation Lines, manual Blast rooms, and dust collector ventilation systems.