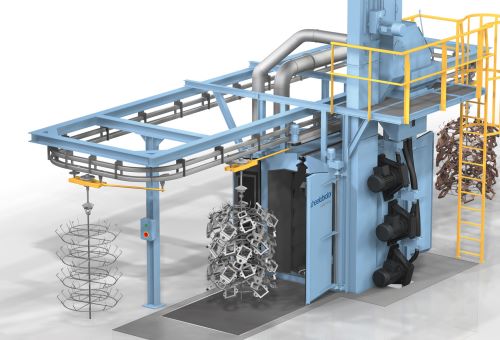

Strahlen von Gussteilen

Sowohl Druckluft- als auch Schleuderrad-Strahltechnologien können zum Reinigen von Teilen in der Eisenbahnindustrie verwendet werden. Faktoren wie die Größe, Komplexität und Anzahl der zu behandelnden Teile bestimmen die Wahl der richtigen Maschine.