Overhead Monorail shot blast machines are the most flexible machine types.

Overhead monorail machines are used when parts can be suspended on hangers and conveyed into or through a blasting chamber.

This method is best utilized when parts cannot be tumbled, resulting in part-on-part damage, or are not suitable for other conveyor types such as roller conveyors or wire mesh belt conveying.

Part can either rotate while in the blasting chamber or pass through the blast zone without rotating.

This highly versatile machine can effectively clean small, medium and large parts.

Overhead monorail machines utilize multiple blast wheels to clean the parts depending on the size.

This type of Wheelabrator equipment is ideal for sand removal and descaling and can be used in non-iron applications as well as some peening applications.

There are two basic variations to overhead monorail machines: Reversing or Continuous.

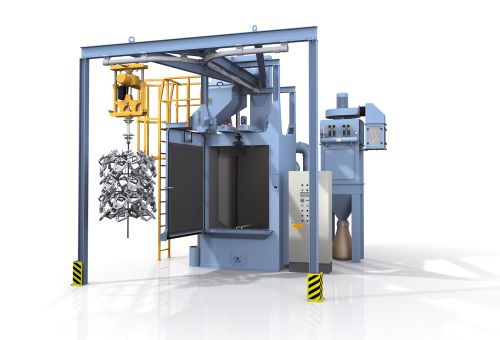

Reversing Type Machines

In these machines, an individual component or a batch of parts enters the blast chamber through the entry work opening, rotates and then exits in reverse through the same opening.

While in the blast chamber, the part moves to multiple positions to improve abrasive impact angles for more effective cleaning.

These machines are best for an off-line work cell and come equipped with a monorail system to move parts from loading position to the machine and back to unloading position.

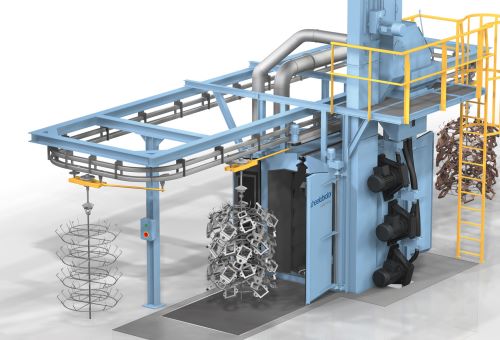

Continuous Type Machines

In these machines, an individual component or batch of parts enters the blast chamber through the entry work opening, rotates or passes through without rotation, and then exits through the exit work opening.

This type of monorail can be in-line with other processes or with a stand-alone loop conveyor for a work cell arrangement.

Related Products

Technology:

Wheelblast

Application:

Cleaning

SmartLine Overhead Rail Machine

Assemble, connect and blast. Immediately ready for use and complete with two blast wheels, you can be in production from day one.

Technology:

Wheelblast

Application:

Cleaning

Overhead Monorail Machine Reversing - HB

Wheelabrator’s Overhead Monorail Machine offers total flexibility for your surface preparation requirements.

Technology:

Wheelblast

Application:

Cleaning

Overhead Monorail Machine Reversing HT

Include a number of heavy duty variations for different production areas, e.g. foundries and forges.

Technology:

Wheelblast

Application:

Cleaning

Overhead Monorail Machine Reversing - HTH

Standard solution ideal for foundry and forge applications, including cast, forge or hardened parts.

Technology:

Wheelblast

Application:

Cleaning

Overhead Monorail Shot Blast Continuous - Spinning

The Overhead Monorail Shot Blast Continuous - Spinning will serve many applications.

Technology:

Wheelblast

Application:

Cleaning

Overhead Monorail Shot Blast Continuous - Non-spinning

Achieves short blasting times due to a combination of the latest transport technology and highly efficient blast wheels.