A cost-effective solution for tumble-proof parts, tumblast and polygon-drum systems are available with a range of shot blast and workpiece handling technologies.

Among the essential advantages of a tumblast system are the compact design, proven operating principle, high cleaning capacity and the gentle tumbling of parts, as well as the complete exposure of all surfaces to the blasting stream.

Solutions for desanding castings and for descaling forgings or heat-treated workpieces include machines in various designs, with steel or rubber conveyors.

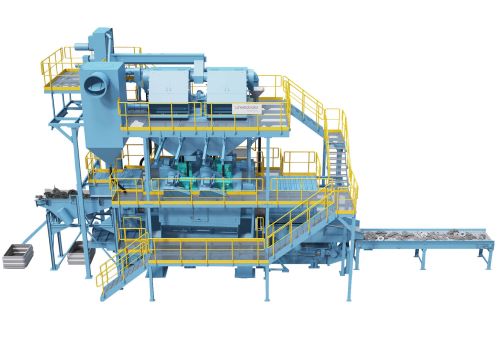

Polygon drum-type machines allow for intensive and gentle shot blasting at high capacity in a polygon-shaped trough rocking back and forth. Automatic loading and unloading provides an almost continuous process with consistent high performance.

Technology:

Wheelblast

Application:

Cleaning

DT Through Feed Rocker Barrel Machine

The principle using drum-type machines is a leading technology today. The polygon shaped trough rocks back and forth to gently tumble the workpieces. Continuous shot blast machines automate production sequences and improve the work environment.

Technology:

Wheelblast

Application:

Cleaning

CT Through Feed Blast Cleaning Machine

CT machines are situated within either an automated process or a continuous production line. The systems are equipped with an endless apron conveyor and between 2 and 6 blast wheels.

Technology:

Wheelblast

Application:

Cleaning

MB Batch Type Tumblast Machine

Compact batch-barrel design with a simple operating principle to deliver forced but gentle turning and tumbling of the parts.

Technology:

Wheelblast

Application:

Cleaning

DTC Batch Type Blast Cleaning Machine

DTC machines are proven in thousands of applications and constitute reliable process technology, high efficiency and flexibility.

Technology:

Wheelblast

Application:

Cleaning

SmartLine Tumblast Machine

Extremely compact and self-contained blasting