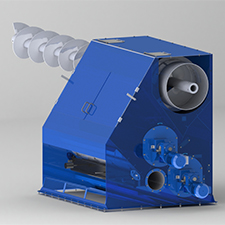

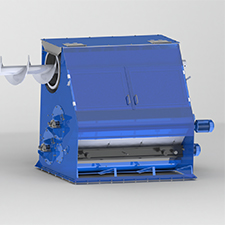

The Wheelabrator® low profile magnetic separator LPM, featuring a magnetic separation system incorporated into an air wash separator, is designed to magnetically separate steel shot from sand or ferrous from non- ferrous material via its magnetic rotating drum.

Unlike a standard air wash unit, this process ensures the consistent removal of sand from the steel shot even under extremely heavy sand loads. The addition of a magnetic separator to a your current blast system may increase the life of the blast equipment as sand is a primary cause of prematurely worn blast equipment

|

Features and benefits

|