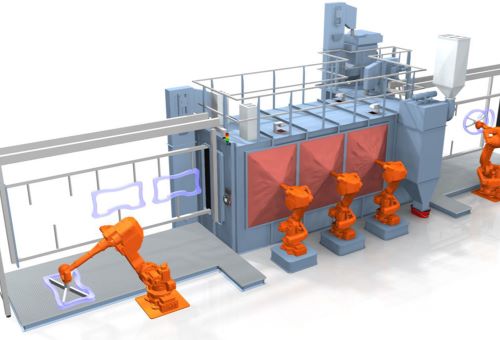

Frame machines

Frame Machines are the most flexible machine types. This type of machine is best suited to processing complex parts which need to be blasted in specific areas located all over the part, for example:

- Motor frame

- Rear frame

- Complete axles

- Tubes for axles

- Car body components

- Structural parts for airplanes

This flexibility is achieved by the ability to adapt the size and number of travelling frames, to the workpiece dimensions and the production rate. On top of these adaptations, the number and position of the blast robots can be adjusted to the customer’s individual requirements.

The use of at least two travelling frames allows an alternate operation of the machine, which reduces the down time significantly.

The travelling frames are accurately positioned in the loading/unloading area, so that this can be performed by robots.

The use of three or four travelling frames enables the machine operation for two production lines without the need for refitting. Refitting of the travelling frames for new devices can be performed manually, automatically by a loading/unloading robot, or by a manual or automatic transfer system.

Wheelabrator offers a full range of highly precise frame machines designed specifically for the aerospace and automotive industries.

Technology:

Airblast

Frame Machines FM

Highly flexible machine range, with two to four frames, for light up to heavy parts.

Technology:

Airblast

MPRF 16000 Robotic Peening and Forming System

Robotic Peening and Forming System with high precision and flexibility, for aerospace wingskin saturation shot peening and peen forming.

Technology:

Airblast

Application:

Shot Peening

MPF 20000 System

This is the ultimate solution for aerospace wingskin saturation shot peening and peen forming. The CNC system high precision and flexibility, combined with a wide range of controlled peening power, allow for complex wing panel forming in a fully automatic mode without corrective peening in most cases.