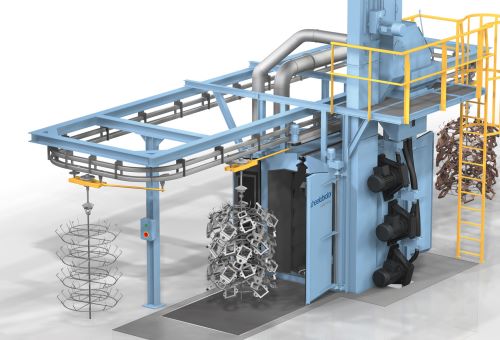

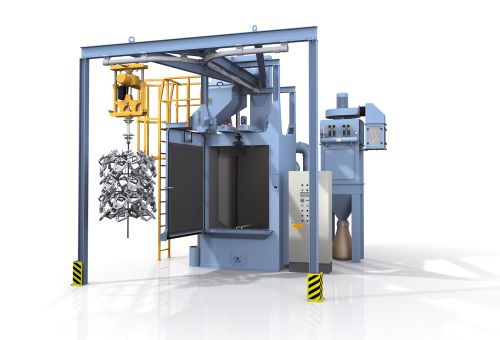

Cast part cleaning

Both air and wheel blast technologies can be used to clean parts of the Rail industry. Factors such as the size, complexity and number of parts to be treated will determine the choice of machine. Visit the Foundry and Forge pages for further information about treating cast parts.