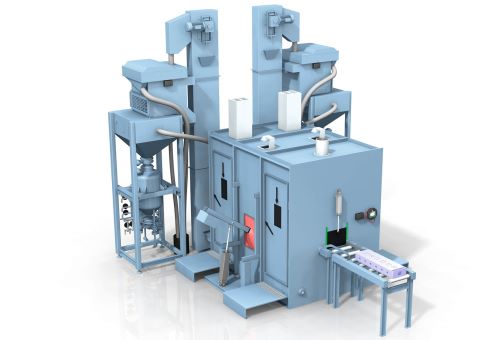

Internal cleaning blasting machines

Internal airblast machines reliably blast interior cavities of simple or complex castings, for example cylinder head bores and water jackets, crank cases, engine blocks and suspension components.

Flexible lances, extra-small nozzles and robot arms can be integrated to exactly position nozzles to blast into component cavities from the outside or to permit deep penetration into apertures to clean around bends and reach deeply buried voids.

Internal machines can blast into apertures as small as 5mm or enter channels and other cavities with a minimum diameter of 11mm. Different areas of larger workpieces can be blasted simultaneously.

Highly flexible modular designs allow these sophisticated machines to be easily adapted, automated and extended to suit a broad range of parts, blast applications and throughputs. Exchangeable blast nozzles can be upgraded to keep pace with changing process needs and a complete process control system ensures repeatability.

Technology:

Airblast

Application:

Internal Cleaning

Advanced Internal Cleaning Machines

Blast cleaning the internal bores of engine blocks and water jackets with flexible lances and nozzles

Technology:

Airblast

Application:

Internal Cleaning

IDS Internal Cleaning Machine

The IDS machine is a special machine for blast cleaning of the internal channels and bores of engine block and cylinder heads with flexible nozzles.