Wheelabrator’s machines for blasting aluminium can help you save money in the context of current industry pressures

As the demand for lightweight components increases and the environmental impact and consumption of resources must be constantly reduced, requirements are ever changing for the surface preparation of die-cast and aluminium parts.

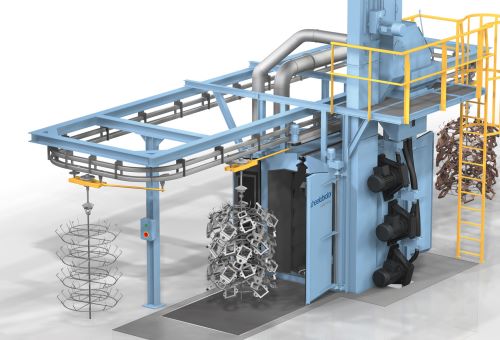

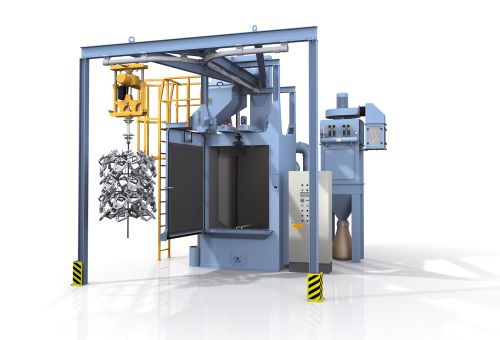

Wheelabrator's shot blasting machines are efficient, reliable and resource saving, and comply with the stringent expectations of aluminium smelters worldwide. The machines are specifically designed for surface treatment and deburring of aluminium parts.

Depending on your application and requirements, standard design or special custom-designed machines are available. Our experts are happy to advise you in detail and work with you to find the suitable solution for your operation and your requirements.

Click on the animation to the right for more details.