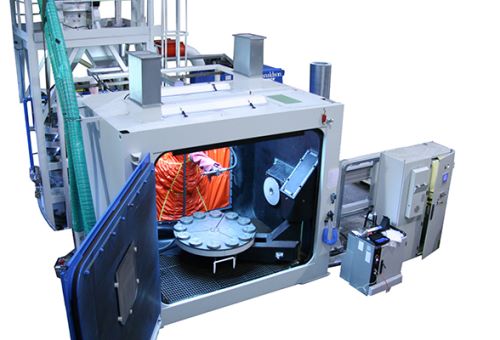

Landing Gear Shot Peening By Airblast Technology

Spot shot peening and/or peening of the entire landing gear can be achieved by airblast techniques utilising multiple nozzles and lances.

A polyarticulated robot or carriage combined with multiple nozzles and lances can operate in a variety of axes to process parts with complex geometries.

In this manner simultaneous shot peening of external and internal surfaces can be achieved.